Professional Services (Your Trust is Priceless!)

-

Professional Pre-sale Service

- Filtration method and equipment recommendation.

- Free CAD or 3D drawing.

- Equipment can be customized.

-

Complete Service During Sales

- On-time delivery.

- Equipment inspection by photo or video.

- Secure and standard package.

-

After-Sale Service

- Installation assistance by a phone call or video.

- Free accessories for maintenance.

- Engineer sent to solve the onsite problem.

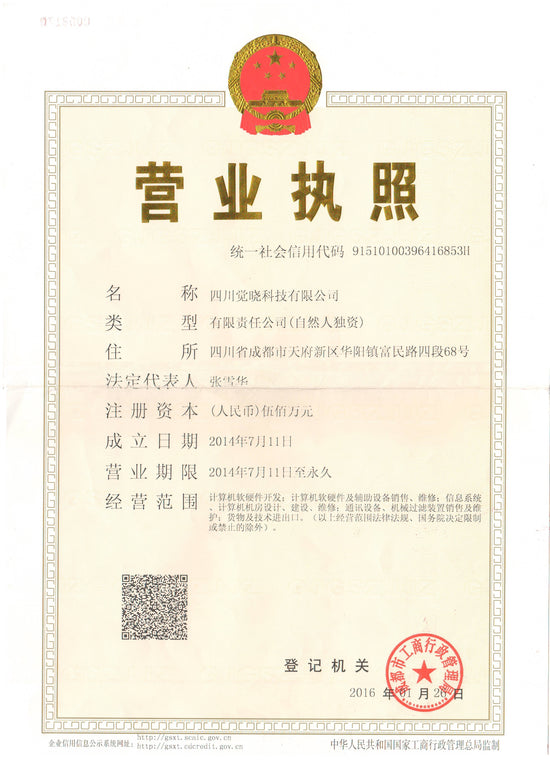

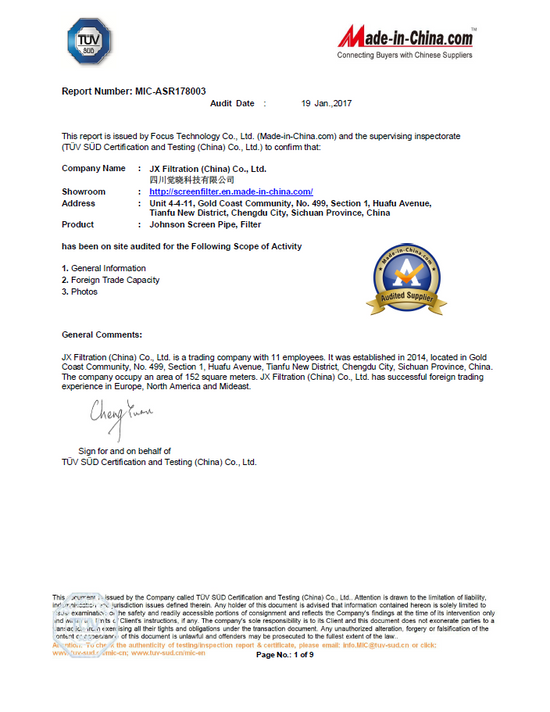

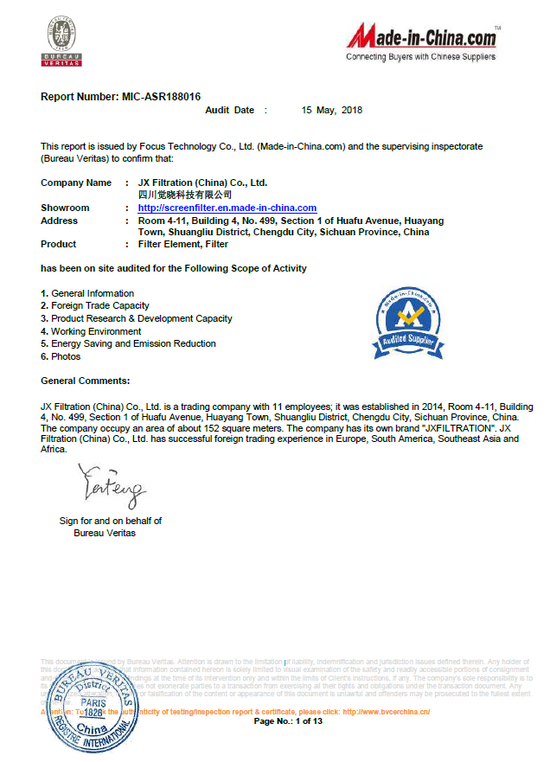

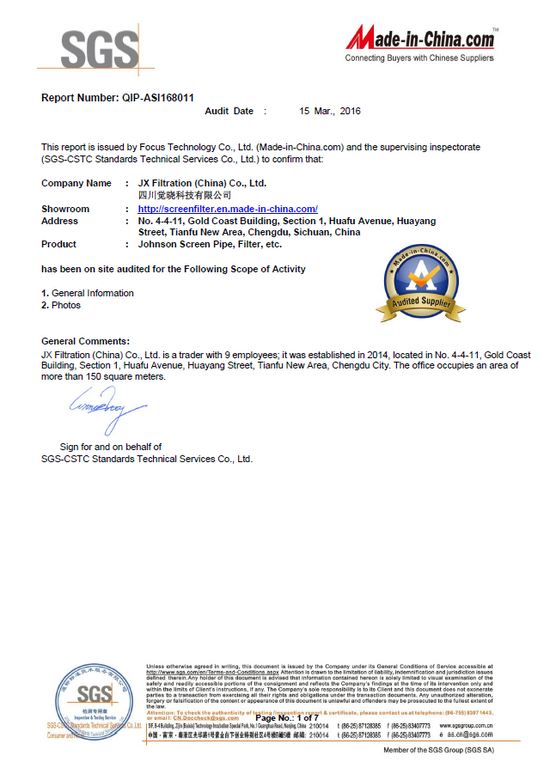

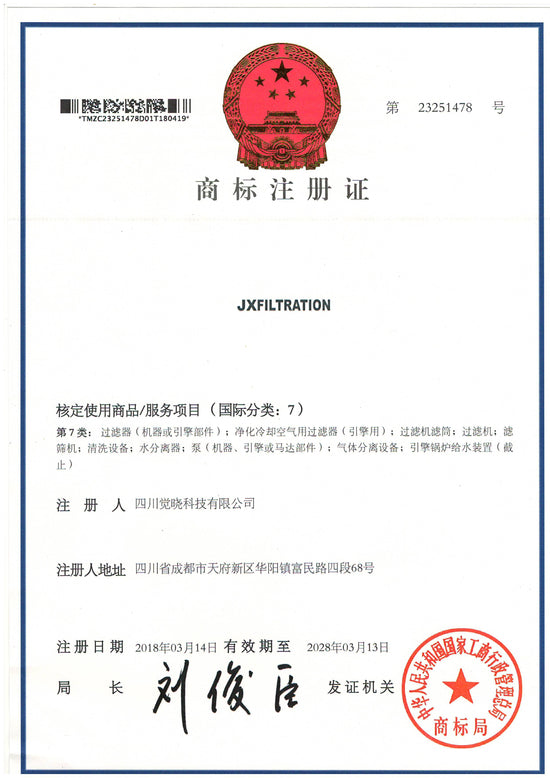

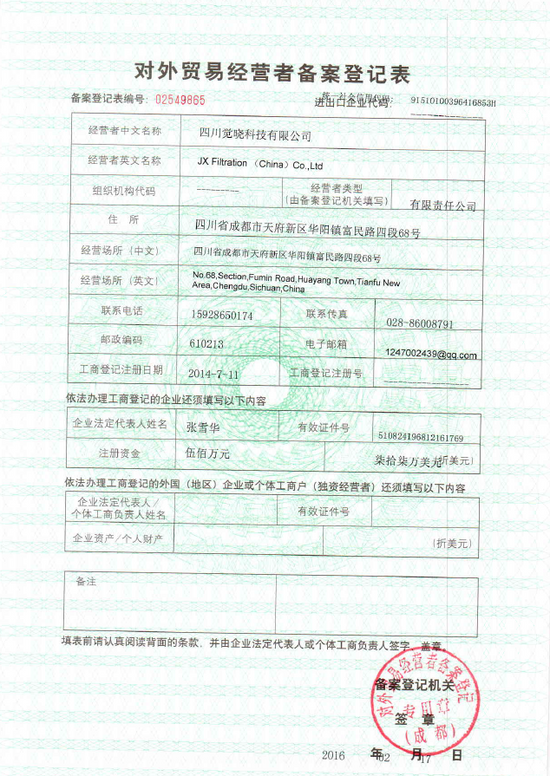

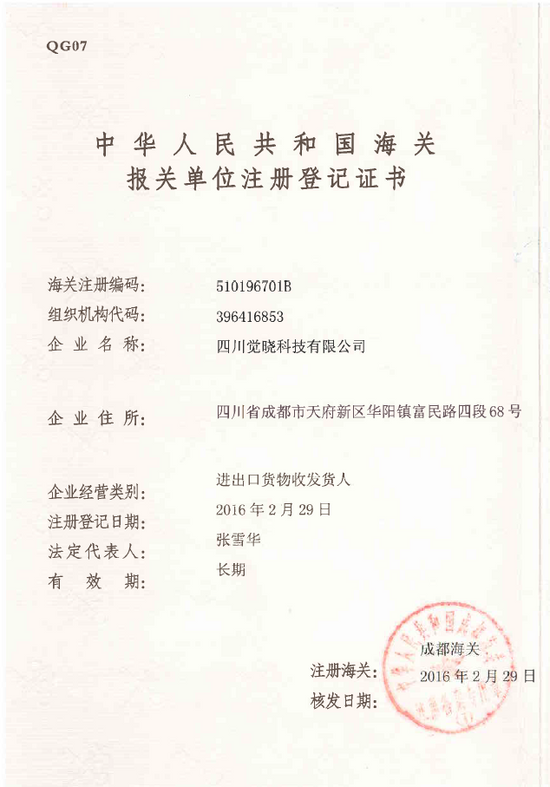

Our Certificates

-

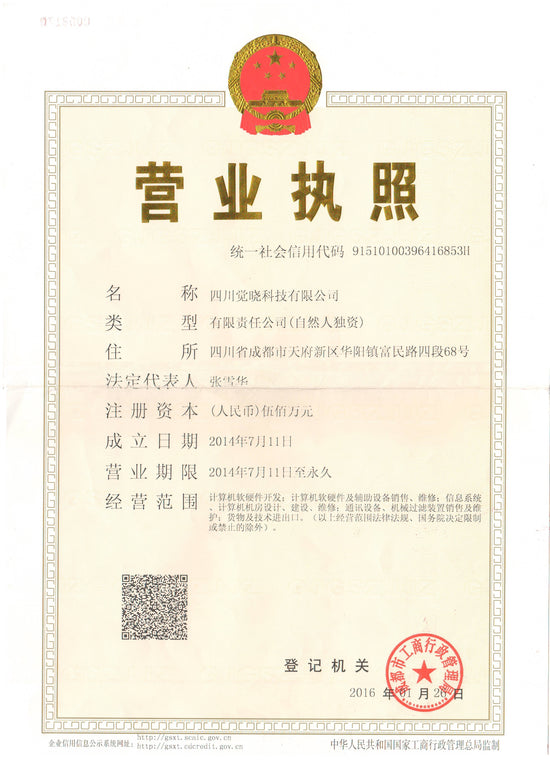

Business License

-

CE

-

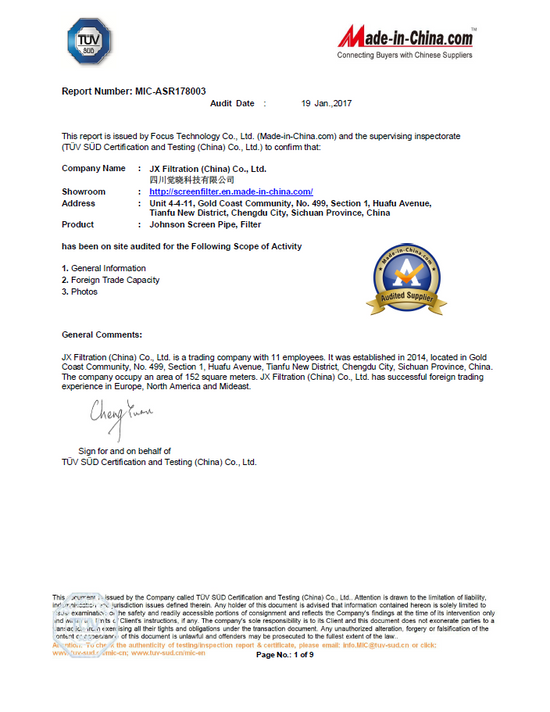

TUV

-

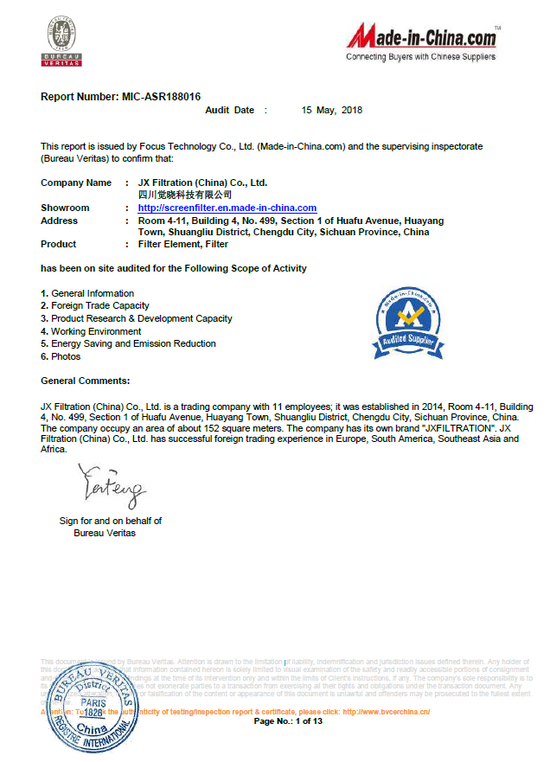

BV

-

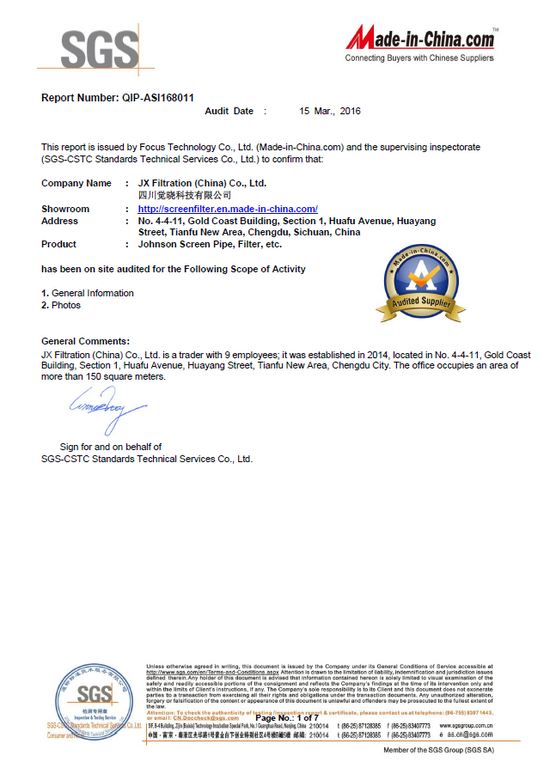

SGS

-

Trademark Certificate

-

Export License

-

Customs License